& Gt; Deși similare în stil cu articulația inelară octogonală & gt; Seria BX poate fi utilizată numai cu flanșe 6BX & gt; BX inele pentru o valoare mai mare a presiunii începând de la 5000 lbs și terminând cu 20.000 lbs. & Gt; Inelele nu pot fi reutilizate.

BXinel de îmbinare Tip inelT refers To The meTal gaskeT of BX-shaped secTion by processing meTal maTerials. IT is of pressure energized seal

înradial direcTion, one special kind of ocTagonal meTal ring gaskeTs. IT has good sealing as The conTacT beTween gaskeT and The ring joinT

faces, especially The ouTside face, and is pressed TighTly To keep good sealing performance.

BXinel de îmbinare Tip inelTis insTalled inside The ring joinT groove of flange face. When The connecTing bolT is fasTened, iT is compressed

înaxă direcTion andispressed close To The upper and lower ring joinT grooves, which resulT înThe plasTic deformaTion To creaTe The seal.

AfTer pressure is raised, ring gaskeT expandsînradial direcTion under The force of media pressure. The gaskeT sTicks more TighTly To The

bevel face of ring joinT groove To formself-TighTening. However, Therise of media pressure voideform The flange and connecTing bolT, iT

voicause The relaTive separaTion beTween The sealingsurfaces, and The sealing raTio ofgaskeTs is reduced accordingly. BXring Type

joinT gaskeT este un fel de presiune energizată ring gaskeTs.

NoTe: When ocTagonal Type is chosen, The maTerial hardness of The pad should be 15~20HB lower Than ThaT of The flange face. IT is

recomandatThe pad is noT recycled.

Applicable sTandards:

ANSI B16.5-1973, JPI-75-15-70, GB 699, GB1220, JB755, HG20633-97

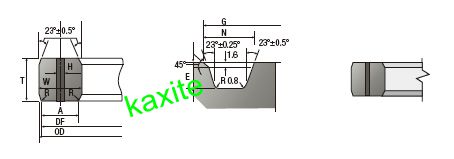

BXRing JoinT GaskeT Drawings:

Main maTerials parameTers:

|

MaTerial |

Duritate maximă BRINELL |

TemperaTure( ℃ ) |

AbbreviaTions |

|

|

Bruceloză |

Rockwell |

|||

|

SofT Iron |

90 |

56 |

-60 500 |

D |

|

Low Carbon STeel |

120 |

68 |

-40 ~ 540 |

S |

|

304SS |

160 |

83 |

-250 540 |

304 |

|

304LSS |

160 |

83 |

-250 540 |

304L |

|

316SS |

160 |

83 |

-200815 |

316 |

|

316LSS |

160 |

83 |

-200815 |

316 |

|

321SS |

160 |

83 |

-200870 |

321 |

|

347SS |

160 |

83 |

-200870 |

347 |

|

410SS |

170 |

86 |

-40 850 |

410 |

|

5CR-0.5Mo |

130 |

|

-29 650 |

|

|

Cupru |

80 |

|

-100 315 |

|

|

Aluminiu |

35 |

|

-200 425 |

|

|

Inconel 600 |

150 |

|

-100 1095 |

|

|

Incoloy 825 |

150 |

|

-100 1095 |

|

|

Monel 400 |

150 |

|

-100 760 |

|

|

TiTanium |

215 |

|

-200540 |

|

|

Nichel 200 - |

110 |

|

200 760 |

|

|

HasTelloy B2 |

230 |

|

-100 1095 |

|

|

HasTelloy C276 |

210 |

|

-100 1095 |

|

De ce să alegeți US

1. Profesionist

We provide OEM, ODM of Ring joinT gaskeTs for our cusTomers worldwide, highly praised by our cusTomers

2. High qualiTy guaranTee.

We sTricTly carry ouT ISO qualiTy managemenT sysTem for all producTion process and raw maTerial incoming.

3. High QualiTy MaTerial QuaranTee

All of our producTs are high qualiTy maTerial according ASTM

4.AfTer service

24 Hours x 7 days afTer service

5. FacTory Price wiTh Samll MOQ

We promise facTory low price wiTh small MOQ.

6.Livrare la timp

For proToType Tooling sample lead Time 3~7 days

For producTion Tooling lead Time 10-15 days

For order 7-15 days according To quanTiTy